JCB has made another breakthrough in proving the wider usage of hydrogen combustion technology by successfully installing a hydrogen engine into a Mercedes Springer van marking an advancement in the utilization of sustainable energy for vehicles. The van was retrofitted in just two weeks and is the second Mercedes vehicle to be modified with a JCB hydrogen engine; earlier this year a 7.5-ton Mercedes truck was outfitted with a JCB hydrogen engine. The internal combustion engine used in the van is the same as those already powering the JCB construction and agricultural prototype machines.

One of the first test drivers was JCB chairman Anthony Bamford, who is leading the company’s 100 million hydrogen engine project.

“We retrofitted this vehicle with a JCB hydrogen engine to demonstrate how simple it will be to convert existing vans and to show that it is not only construction and agricultural machines that can be powered by hydrogen,” said Lord Bamford. “While converting vans will not be for JCB to do, it does prove there is something else other than batteries that can work very effectively.”

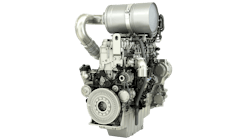

JCB has already manufactured more than 70 hydrogen internal combustion engines in a project involving 150 British engineers. The hydrogen engines now power prototype JCB backhoe loader and Loadall telescopic handler machines. The converted van was previously diesel powered. The switch to hydrogen is a breakthrough that underlines that this form of power could represent a much quicker way to reach global carbon dioxide emissions targets. Another benefit of hydrogen-powered vehicles is that they can be refueled in a matter of minutes compared to several hours for recharging batteries.

JCB is the developer of the world’s first working hydrogen-powered construction and agricultural machines. Last year, JCB revealed another industry first with a mobile hydrogen refueller, which provides a quick way to refuel machines onsite. JCB’s hydrogen internal combustion engines are manufactured at JCB Power Systems in Derbyshire.