Category: Engines/Power Sourcing

Manufacturer: Perkins

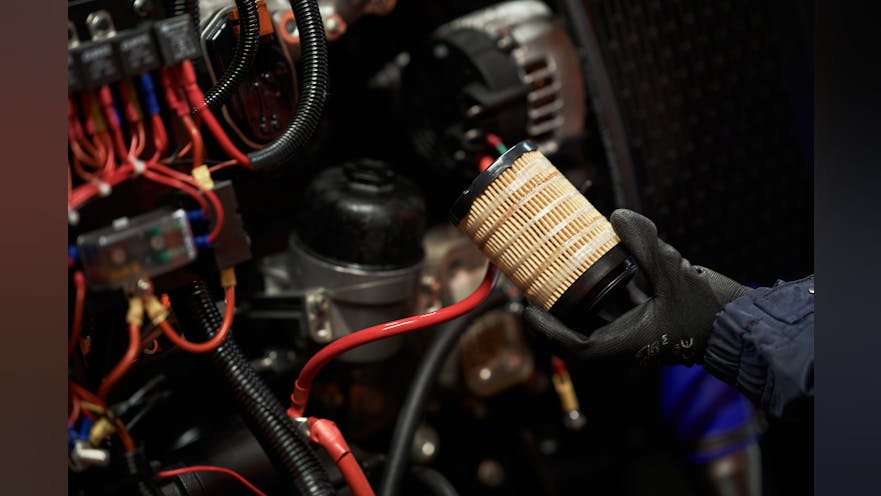

Product Name: EcoPlus oil filter

Key Innovation: Perkins Ecoplus filters oil filters use a replaceable element inside a reusable filter housing. This eliminates the disposable metal canister, keeping them out of landfills, and the Ecoplus filter can be incinerated where local regulations allow.

Manufacturer’s Description: Typically, off-road diesel engines use spin-on oil filters. Our filter provides two major advantages over spin-on filters:

1. Reduces environmental impact through elimination of the one-use steel or aluminum case common in spin-on filters.

2. Eliminates the mess often associated with changing a spin-on oil filter.

Perkins Ecoplus oil filters use a replaceable element inside a reusable filter housing. This eliminates disposable metal canisters, keeping them out of landfills, and the Ecoplus filter can be incinerated where local regulations allow. They have no metal content, are smaller, have higher quality media and use a glass-filled nylon body housing that is tough and withstands extreme changes in temperature.

The Ecoplus oil filter design also allows the filter to be mounted upright on the engine, making it easier to access. A technician simply unscrews the top cover using the 38-mm nut, lifts out the cap and element and clicks the new filter back in place. No special tooling required. The filter includes an improved bypass valve in the filter housing. It is permanently mounted to the filter housing where it is less likely to open inappropriately. And, because the filter stays full of oil, the engine primes quickly, improving start-up protection.

The media used in Perkins Ecoplus oil filters feature spiral roving that reduces pleat flex and fatigue while maximizing filter surface area and increasing contaminate retention; acrylic beading that prevents bunching and maximizes surface area; urethane end caps that seal against the housing to eliminate potential leak paths; and a non-metallic center tube that is stronger and cleaner than metal that reduces the potential for harmful swarf. The end cap design also prevents the filter element from being installed incorrectly. Working together, these features combine fast oil circulation when the engine starts to protect turbochargers and other components sensitive to contaminants.

RER interviews Siobhan Scott, marketing manager, Perkins Engines:

One of the first benefits to Perkins’ EcoPlus filter is environmental. Because it uses a replaceable element inside a reusable filter housing there is no disposable metal canister to end up in a landfill. But there are other benefits, explains Siobhan Scott, Perkins marketing manager, aftermarket.

“One of them is how it actually works when we have a reusable housing,” she says. “Then there is the fact that the filter itself is very high-quality and it’s really easy and clean to change. So there really are three important benefits: the environmental benefit, the actual working of it and how they operate when you change them.

“What we’ve done is combine a reusable bypass valve with a reusable metal container and put a high-quality filter between them. The filter is the only part you replace, so when you’re thinking about disposal you’ve got far less material involved, which is great. And because the by-pass valve is permanently mounted to the filter housing a high-quality bypass valve can be used which is less likely to open inappropriately. That’s really important for engine protection and the environmental benefits are that you’re only buying what you need.”

Perkins also redesigned the positioning of the oil filter so that when it is changed, the old oil doesn’t spill. The filter is mounted upright on the engine, making it easier to access for element changes. The technician just has to unscrew the top cover, lift out the cap and element and click the new filter back in place. No special tooling is required.

As for the filter itself, Perkins has put a lot of new technology into it and has eight patents pending on the filter. “There are three key things in the design of the filter that makes it work really well,” says Scott. “The first is what’s called a molded end pack which means the urethane end caps seal against the filter housing. There’s no gap for the oil to get through, making it more likely that all the oil is being filtered.

“Then, we’ve done two things to keep the media pleats in place. One, we put in an acrylic bead between every single fold. That stops them squashing together because they’re being held apart. And, two, we put what we call spiral roving around the media to hold the pleats in place. So together that means that all the oil is being filtered really well.

“And the actual filter material is really high quality, it’s made out of cellulose and a product called meltblown. So it’s really good high quality filter material to ensure that you’re protecting your engine.”

Scott adds that the metal center tube used in a traditional spin-on filter can become corroded or rusted and shed pieces of metal that go around the engine with the oil.

“We have a non-metallic center tube so it can’t rust which makes it much better for keeping the oil clean. If you’ve filtered your oil and then it picks up swarf from the metal center tube, then you’ve gotten rid of one bad thing but you’ve added another. With high-quality filter media held in place, a non-metallic center tube and a high-quality by-pass valve you’ve got clean oil going around your engine and that’s the key to all of this.”

Another benefit, Scott explains, is that oil flows immediately when the engine starts.

“You don’t want your turbocharger operating without any oil while it’s waiting for oil to arrive. The minute you turn on the engine, the oil will start circulating from the by-pass valve, it’s going to have that oil ready to start going around the engine protecting all your important components.

”So, by combining a high-quality by-pass valve with good quality filter media held in place really carefully you get a really good quality filter that protects the engine. Well filtered oil means you don’t get scratches as it’s going around. You’re protecting the rest of your engine by having that high quality by-pass valve that allows you to pass the oil around the engine straightaway.”